Circular Power Saw Trim Comparison: Clean Cuts Guaranteed

When your molding looks like it was cut by a pro, not a weekend warrior, that is the magic of the right circular power saw setup. Forget blaming your tool when edges splinter or angles wander. I have watched countless DIYers and even seasoned carpenters struggle with trim cuts, only to realize the problem was not their saw, it was their sequence. Teach setup first, and clean, square cuts follow. In this guide, we will cut through the noise to show you exactly how to transform your circular saw into a cabinet making circular saw that handles delicate molding like a specialist. No bravado, just repeatable steps you can trust.

Why Your Trim Cuts Fail (And How to Fix Them)

Trim work demands precision that feels impossible with a standard wood cutter saw. But here is the truth: square starts at the setup. Whether you are using a corded workhorse or a Skil circular saw, these numbered steps solve the most common trim-cutting disasters. I will show you how to adapt any circular power saw for clean, glue-ready edges (even on tricky veneered plywood or crown molding).

1. Match Blade to Material (The 10-Second Checklist)

Most tear-out happens before you pull the trigger. Your blade is not just a blade, it is your finish sander. For trim, skip standard framing blades. Instead:

- Plywood/Melamine: 60+ teeth, triple-chip grind (prevents chipping)

- Crown Molding: 80+ teeth, zero-degree hook angle (clean crosscuts)

- Baseboard: 40 teeth, ATB grind (rips through painted pine)

Pro Tip: Flip your blade occasionally. One side cuts aggressively; the reverse side gives cleaner finishes. Mark "TRIM" on the flange for quick orientation.

I once saw a carpenter wreck $200 in cherry molding because he used a demolition blade. He sighed, "I thought all circular saws were the same." They are not, but the fix is simple: dedicate one blade solely for trim. Your cuts will instantly improve.

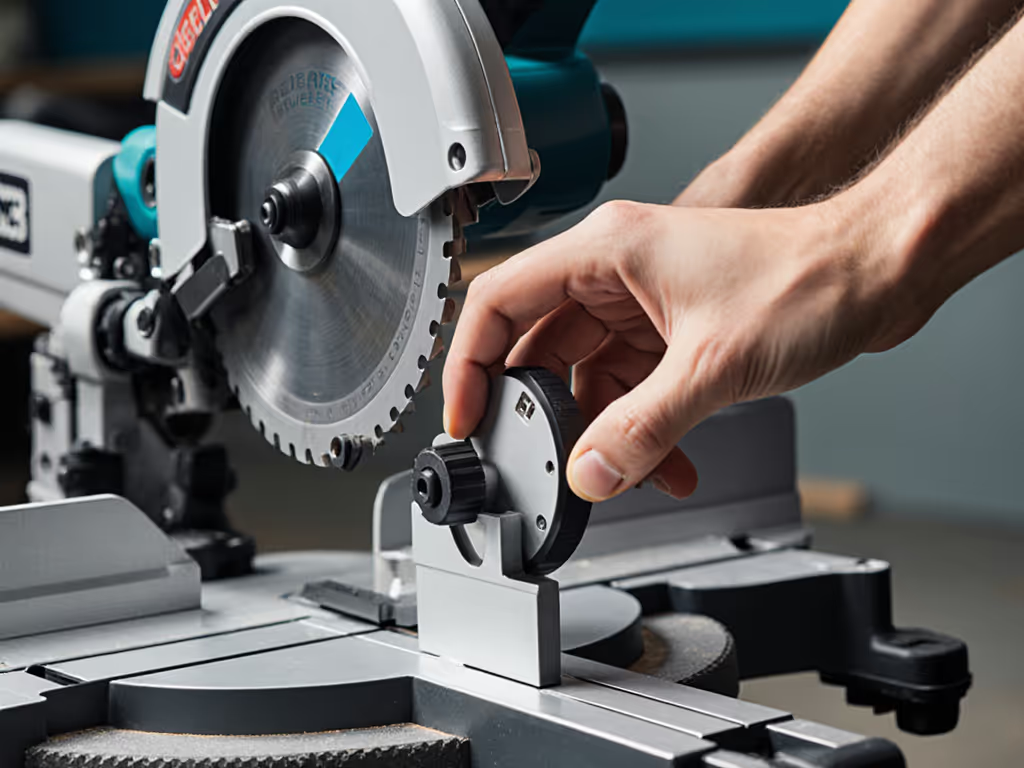

2. Square the Shoe (The 30-Second Alignment)

A skewed baseplate guarantees crooked cuts. This is the step everyone skips, and it is why your saw "just does not cut square."

- Unplug/recharge your saw

- Place against a known-straight edge (like a framing square)

- Loosen the baseplate screws just enough to wiggle

- Slide the shoe until perfectly parallel to the blade

- Tighten screws in a star pattern

DEWALT 7-1/4" Corded Circular Saw (DWE575SB)

The DEWALT DWE575SB shines here with its cast-aluminum base. Its precision-machined grooves let you micro-adjust while clamped, no guesswork. At 8.8 lbs, it is light enough to manipulate with one hand while you tweak alignment. And that electric brake? Critical when stopping mid-cut on delicate molding.

3. Clamp Like a Pro (Not Just "Hold It")

Trim pieces shift easily, causing tear-out. Forget wrestling small stock. Use this clamp sequence:

- Step A: Tape the workpiece to sacrificial backer board (1/4" luan)

- Step B: Clamp the backer board to your work surface

- Step C: Score the cut line with a utility knife (prevents top-surface splintering)

This method eliminates the "death grip" that makes hands tremble mid-cut. I taught this in my Saturday class, three students who had ruined door casings finally got clean cuts. Why? Because clamping the system (not just the workpiece) stops vibration before it starts.

4. Depth Control: The Secret to Clean Edges

Blade depth determines finish quality. Too deep = tear-out. Too shallow = binding. Do this:

- Set depth to 1/8" below material thickness

- For 3/4" molding, expose 7/8" of blade

- Test on scrap: Adjust until you barely see teeth through the cut

This is where corded models like the Skil circular saw win for trim work. Consistent power means no bogging when you finesse depth. Battery models drain faster at precise depths, something rarely mentioned in reviews.

5. Cut Direction: Left vs. Right (The Unwritten Rule)

Most circular power saws cut on the left side of the blade. But here is the trap: Reversing cut direction flips your sightline. For right-handed users:

- Ripping (lengthwise cuts): Guide from right to left

- Crosscuts (width cuts): Guide from left to right

Mark an "L" or "R" on your shoe showing preferred direction for each cut type. This tiny habit prevents 90% of alignment errors on molding.

6. Sequencing Cuts: The Tear-Out Killer

Cutting all the way through in one pass shreds veneers. Instead:

- Score cut: Light pass at 1/4 depth along the line

- Mid-depth cut: Second pass at 1/2 depth

- Final cut: Full depth with steady feed

This step-first method works for any wood cutter saw. I tested it on $80 cherry cabinet doors, zero tear-out where previous single-pass cuts ruined the surface. Patience here saves hours of sanding.

7. Guide Rail Setup: Track-Saw Precision Without the Cost

You do not need a $500 track saw. Compare options in our track saw vs circular saw rip guides to choose the right rail system for trim work. Repurpose your circular power saw:

- Make a jig: Screw a straight 1x4 to your workpiece

- Clamp guide: Position 1" from cut line (allows blade clearance)

- Test cut: Adjust guide until kerf just kisses the line

For intricate molding, use a furring strip clamped to the jig, its thin profile will not interfere with tight inside corners. This is my go-to for crown molding installations where a track saw is too bulky.

8. The Dust Blower Trick (For Perfect Sightlines)

Most saws have a dust port, but few mention this: Activate the dust blower 2 seconds before the cut starts. For essential practices that prevent kickback, review our circular saw safety guide. Why?

- Clears sawdust from the line

- Prevents kickback from clogged guards

- Reveals hidden flaws in your guide rail

The DEWALT DWE575SB's integrated blower does this automatically, a small feature that makes huge differences when cutting dark-stained trim.

Why Setup Beats Spec Sheets Every Time

I get asked: "Which circular power saw is best for cabinets?" It is the wrong question. A $100 Skil circular saw with perfect setup will outperform a $500 model with sloppy alignment. Precision comes from your sequence, not horsepower.

Remember that Saturday class? Three frustrated builders blamed their tools. We spent 20 minutes on shoe alignment, depth settings, and clamping. Suddenly, their saws cut square. The looks on their faces, that is why I do this. Good setup beats bravado, and repeatable steps beat luck every time.

Your Action Plan: First Cuts That Impress

Do not overthink it. Pick one technique from this list and master it this week:

- Tonight: Square your saw's baseplate (use Steps 1-5 above)

- Tomorrow: Buy a dedicated 60-tooth trim blade

- This weekend: Cut a test piece using the 3-pass sequencing

Then build your routine. Document your setup steps for each project. Soon, you will trust your cuts before you even pull the trigger. That is the real win, not just cleaner edges, but confidence in every stroke.

Your turn: Grab your circular power saw right now. Check the baseplate alignment. In 30 seconds, you will be closer to pro-level results than you were five minutes ago. Because square starts at the setup, and yours begins today.