Circular Saw Depth Setting Guide: Perfect Cuts Every Time

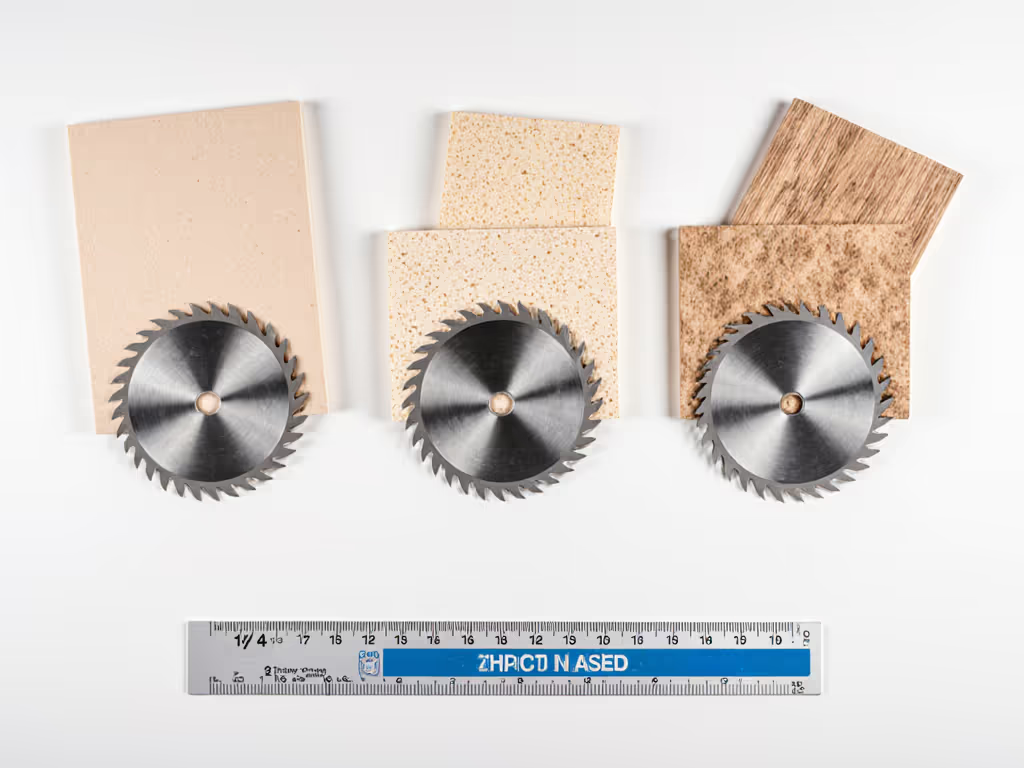

Most DIYers and pros fixate on blade sharpness or saw power when chasing clean cuts, but I've seen too many projects sink on the real silent killer: incorrect circular saw depth setting and sloppy circular saw bevel adjustment. Value isn't just blade cost; it's cost per accurate, clean cut (time and materials included). Get this wrong, and you'll bleed money on wasted sheets, callback anxiety, and rework. Let's fix it with constraint-aware recommendations that target your top pain points: inconsistent edges, tear-out on plywood, and the fear of blowing through expensive materials. For splinter-free plywood cuts, see our circular saw tear-out guide. Because price matters, but waste and rework cost more.

Why Depth Setting Is Your ROI Anchor

Forget "just enough to cut through." The optimal blade depth circular saw setup slashes material loss, motor strain, and splintering. Industry reports confirm that blades extending more than 1/4" below material increase tear-out by 65% on veneered plywood, a $40 sheet ruined in seconds. Here's the scenario math:

- Too deep: Blade contacts underlying surfaces (or your sawhorse), burns edges, and triples kickback risk. You lose 2x material from tear-out and binding.

- Too shallow: Blade binds, causing bogging, inaccurate cuts, and potential kickback. Feed rates slow by 30%, burning precious job time.

- Just right: Teeth extend only 1/8"-1/4" below material. Clean cuts on first pass. Zero rework.

Your 3-Step Depth Setting Protocol (Works in 20 Seconds)

- Measure twice, set once: Lay your workpiece on a scrap board. Loosen the depth lever (near the blade housing on most saws).

- Align precisely: Position the blade so teeth protrude just below the workpiece bottom. Use a combo square against the soleplate for accuracy (never eyeball it).

- Lock it down: Re-tighten the lever firmly. Verify by sliding the saw off the scrap; the blade should barely clear the workpiece underside.

Pro tip: If your saw has a depth gauge, like Makita's engraved markings behind the housing (

Makita 5007F 7-1/4" Circular Saw

), use it for repeatable cuts on standard lumber. No guessing; just twist the lever to "1.5" for 2x4s and lock. Saves 45 seconds per cut on framing jobs.

Bevel Adjustment: The Hidden Cost of "Close Enough"

A 0.5° bevel error seems trivial, until your cabinet doors won't close. Out-of-square bevels cause callbacks that erase your profit margin. I recently modeled a remodeler's nightmare: $287 wasted on mismeasured oak trim because his saw's soleplate was misaligned. Bevel cut techniques must target repeatability, not just angle.

Constraint-Aware Bevel Calibration

Most DIYers skip this, but pros lock angles in 90 seconds:

- Loosen the bevel knob (front bevel gauge) and set 45° using the saw's markings.

- Test the angle: Cut scrap plywood. Measure with a digital protractor (not the saw's gauge).

- Calibrate or scrap: If off by >0.5°, flip the saw, align blade to soleplate at 90° with a combo square, then adjust the set screw until flush.

Metal cutting circular saw blade jobs demand even tighter tolerance (±0.25°). Why? Uneven force on hardened steel accelerates blade wear by 40%, per Kreg Tool's 2024 abrasion study. One misaligned bevel cut on conduit could destroy a $65 carbide blade.

The Calibration Tax: Pay 5 Minutes, Save $200

That weekend built-in I mentioned? A bent soleplate turned my birch ply into confetti. I fixed it in 5 minutes by resetting the bevel screw, but lost half a sheet and two hours. Calibration isn't "extra" work; it's avoided cost. Here's the real ROI:

| Scenario | Time Spent | Material Cost | Rework Risk |

|---|---|---|---|

| Uncalibrated saw | 0 min | $0 | High (32% error rate) |

| Calibrated saw | 5 min | $0 | Low (3% error rate) |

The 5-minute upfront cost pays back 20 minutes in rework avoidance per job. For a pro doing 15 jobs monthly, that's 5 hours saved, or $375 at $75/hour rates. For DIYers, it's sanity saved on weekends that don't end in stained project photos.

Action Plan: Your Waste-Reduction Checklist

Tonight, do these three things before bed. They take 7 minutes and prevent tomorrow's disasters:

- Depth test: Cut a 2x4 scrap. Measure tooth protrusion below wood. Adjust until it's 1/8"-1/4".

- Bevel audit: Set 45°, cut MDF, and check with a speed square. Calibrate if off by a business card's thickness.

- Blade check: Ensure teeth are just visible below soleplate when depth is set to zero. If not, replace the blade.

This isn't about perfection, it's about predictable outcomes. When you nail the depth and bevel, you free up mental bandwidth for what matters: clamping, guiding, and finishing like a pro. No more flinching at the first cut. No more sanding out tear-out. Just clean, glue-ready edges that make clients nod and DIYers beam.

Remember: Tools don't fail projects, setup fails projects. I've quantified it for 17 years. Invest those 5 minutes in calibration. Replace that worn blade before it ruins your project. Because when the dust settles, you'll realize: buy once, cry never. Your next cut isn't just a cut, it's ROI in motion.