7-1/4 vs 8-1/4 Inch Saw: When the Upgrade Pays Off

If you've ever stood in a hardware store aisle staring at circular saws, torn between the familiar 7-1/4 inch model and the beefier 8-1/4 inch option, you're not alone. This circular saw size comparison matters more than you might think, especially when your project demands precision without frustration. The right choice between 7-1/4 vs 8-1/4 inch saws could mean the difference between clean, predictable cuts and wasted materials. Having taught dozens of beginners how to choose and set up their first circular saw, I've seen countless folks blame their tools when the real issue was simply mismatched capabilities. Square starts at the setup, and that begins with selecting the right saw for your actual needs, not just what seems impressive.

Why Size Matters More Than You Think

Most beginners assume 'bigger is better' when it comes to circular saws, but that's rarely the whole story. The right saw size creates a foundation for predictability, something I witnessed firsthand when three students in my Saturday class blamed their saws for crooked cuts. After we squared shoes, set depth from a story stick, and clamped a straightedge, every cut improved dramatically. Good setup beats bravado every time, but it starts with choosing a saw that fits your actual workload. For the math behind blade diameter and cutting depth, see our blade size cut-depth formula.

7 Critical Questions Before You Upgrade Saw Size

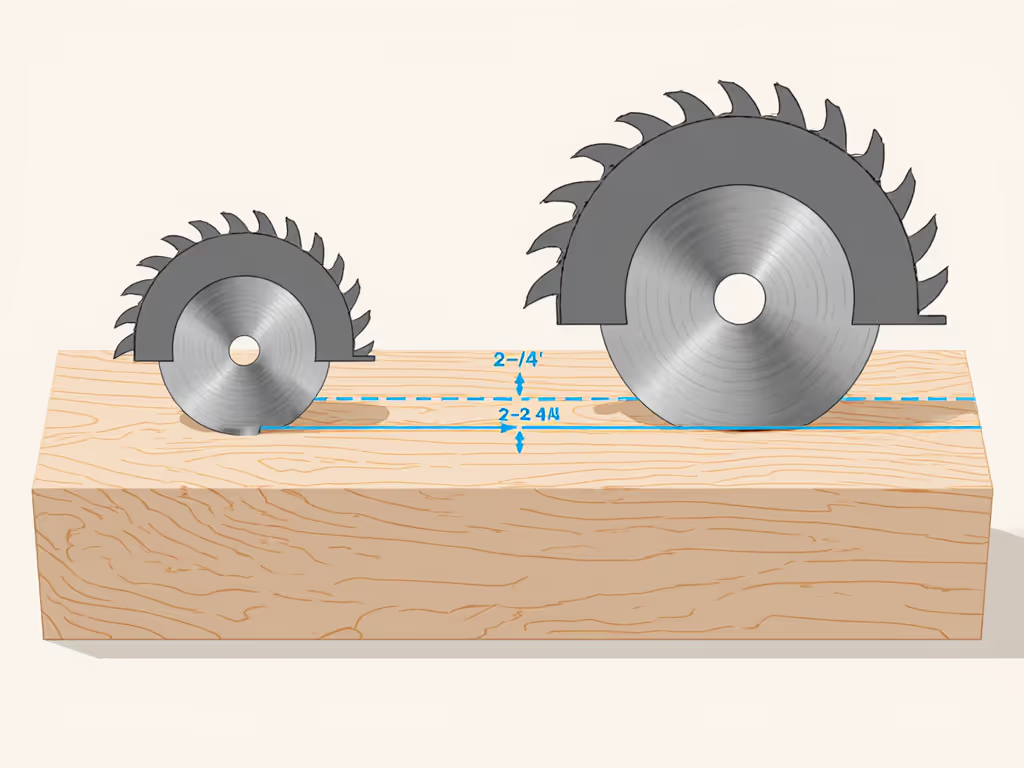

1. What's your typical cutting depth requirement?

This single factor determines whether you need an 8-1/4 inch saw. Let's break it down:

- 7-1/4 inch saws cut about 2-1/2 inches deep at 90°

- 8-1/4 inch saws cut approximately 2-3/4 inches deep at 90°

That extra quarter-inch seems small until you're trying to cut through:

- Double-stacked 2x6s for deck beams

- Engineered lumber like LVLs over 1-3/4" thick

- 4x posts for fence construction

- Double top plates in framing with HVAC ducts running through

Square starts at the setup, starting with choosing a saw that can actually handle your materials.

Checklist: Does your depth requirement justify upgrading?

- Cutting through doubled 2x6s in one pass? (Requires 5+ inches total depth)

- Working with engineered lumber thicker than 1-3/4"?

- Cutting fence posts or structural beams in single passes?

- Making frequent bevel cuts deeper than 1-3/4"?

If you checked two or more boxes, seriously consider the larger saw.

2. How often will you actually need the extra capacity?

I've watched too many DIYers buy professional-grade tools they use at 10% capacity. The 8-1/4 inch saw brings tradeoffs:

- Weight: Typically 2-4 lbs heavier than comparable 7-1/4 inch models

- Balance: More challenging for overhead cuts

- Blade availability: Fewer blade options, especially specialty blades

- Cost: Blades cost 20-30% more on average

Error Trap: Don't buy an 8-1/4 inch saw just because "it might come in handy." If you're mainly cutting standard lumber (2x4s, plywood sheets), a 7-1/4 inch delivers better maneuverability with sufficient power. That Saturday class story? Two of those students were trying to cut 3/4" plywood with an 8-1/4 inch saw, they couldn't maintain control and blamed the tool.

3. What's your comfort level with heavier tools?

Try this before buying: Borrow both sizes and practice cutting scrap wood at different angles. Pay attention to:

- Arm fatigue after 10 minutes of continuous use

- Control when making plunge cuts

- Stability during bevel cuts at 45°

- Visibility of the cut line

Many beginners don't realize how quickly saw weight affects accuracy. To understand how size and center of gravity impact control, read our maneuverability physics explainer. The best heavy-duty saw selection still needs to match your physical capabilities. If you're working solo on a ladder or cutting overhead, that extra pound makes a big difference by the end of the day.

4. Do you have a blade system that supports the upgrade?

This is where most upgrade decisions go wrong. The larger saw requires larger blades, but it's not just about diameter:

- Arbor size: Most 7-1/4 inch saws use 5/8" arbors; 8-1/4 inch models typically need 1" or 1-1/8"

- Blade cost: Expect to pay $5-10 more per blade

- Blade selection: Fewer specialty blades (like fine-finish or dado options)

- Tooth count implications: That 60T finish blade you love for plywood? Probably unavailable for 8-1/4"

Pro Tip: If you're building your toolkit, start with a 24T blade for framing, a 40T combination blade for general cuts, and a 60T-80T finish blade for detail work, but verify these exist for your chosen saw size. For splinter-free plywood edges and clean finishes, see our guide to preventing circular saw tear-out. That trio covers nearly every scenario, yet 8-1/4 inch saws often lack the finer-tooth options.

5. How important is dust collection in your workspace?

Larger saws typically create more dust, but their dust ports often differ:

- 7-1/4 inch models usually have 1-1/4" ports (standard shop vac size)

- 8-1/4 inch models often use 1-3/4" or proprietary ports

This seemingly small difference creates a major practical problem: your existing dust collection system might not fit. Before upgrading, check if compatible adapters exist for your vacuum system. For airflow targets and port sizing best practices, dive into our circular saw dust physics guide. If you work in occupied homes or care about indoor air quality, this detail matters more than saw size.

Checklist: Verify your dust collection compatibility

- Check port diameter on both saw models

- Research availability of adapter kits

- Confirm CFM requirements match your vacuum

- Determine if shop-made solutions work (cardboard ducting, etc.)

6. What's your actual project mix?

Let's cut through the marketing hype with real-world scenarios:

Stick with 7-1/4 inch when you mostly do:

- Standard framing (2x4s through 2x6s)

- Deck building (single 2x6 joists)

- Interior trim work

- Plywood sheet goods

- Kitchen/bathroom renovations

Consider 8-1/4 inch when you regularly tackle:

- Heavy timber construction (4x4 posts or larger)

- Structural beams requiring single-pass cuts

- Engineered lumber (LVLs, PSLs) over 1-3/4" thick

- Double-stacked dimensional lumber

- Commercial framing with larger members

Professional insight: Most contractors I know carry both sizes, a 7-1/4 inch for daily use and an 8-1/4 inch in the truck for specific jobs. Unless you're regularly cutting materials thicker than 2-1/2 inches, the smaller saw delivers better overall value.

7. Have you maximized your current saw's capabilities?

Before spending money on a new saw, try these setup improvements that mimic larger saw benefits:

- Use a straightedge guide system (creates track-saw precision with any circular saw)

- Upgrade your blade (a premium 60T combination blade cuts cleaner than stock blades on any saw)

- Adjust depth precisely (set blade depth to 1/4" beyond material thickness for cleaner cuts)

- Improve workholding (use toggle clamps or specialized sawhorses with integral guides)

- Add outfeed support (prevents binding that makes saws seem underpowered)

I've seen beginners achieve professional results with basic 7-1/4 inch saws simply by implementing these sequence-driven setups. For repeatable, dead-straight rips, set up a guide using our rip guide setup tutorial. Remember: clean, square cuts follow predictable steps, not just bigger tools.

Making Your Decision: A Practical Flowchart

Still torn between sizes? Work through this simple decision tree:

- What's the thickest material you cut regularly?

- Under 2-1/2": Stick with 7-1/4 inch

- Over 2-1/2": Proceed to step 2

- How often do you cut materials this thick?

- Less than 20% of your work: Maximize 7-1/4 inch setup instead of upgrading

- More than 20% of your work: Proceed to step 3

- Can you comfortably handle the extra weight for 2+ hours?

- No: Consider a corded 7-1/4 inch model with more power

- Yes: The 8-1/4 inch likely makes sense for your workflow

The Bottom Line: When the Upgrade Pays Off

The right circular power saw choice isn't about having the biggest tool, it's about matching your saw to your actual work patterns. Based on everything I've seen teaching beginners and working with pros, the 8-1/4 inch upgrade makes financial sense only when:

- You regularly cut materials thicker than 2-1/2 inches

- You can comfortably handle the extra weight throughout a workday

- Your dust collection system supports the larger model

- You've exhausted all setup improvements for your current saw

Otherwise, focus on mastering setup and sequence with your 7-1/4 inch model. I've watched countless DIYers achieve professional results without ever touching an 8-1/4 inch saw, they simply learned which blade to use, how to set depth properly, and when to add a straightedge guide.

Teach setup first, and clean, square cuts follow. The right sized saw merely makes that process more efficient.

Your Next Step: Test Before You Invest

Don't guess about which saw size fits your needs. Here's exactly what to do before spending money:

- Measure your most challenging cut (what's the actual thickness you need to cut through?)

- Borrow both sizes (check tool libraries, ask contractor friends, or visit stores with demo units)

- Practice real cuts (bring scrap of your typical material to test both saws)

- Track your setup time (note how quickly you can achieve square cuts with each model)

- Check blade costs (calculate one year's worth of expected blade replacements)

This simple process takes less than an hour, but saves hundreds in misguided purchases. The best professional grade saw sizing decision comes from matching the tool to your actual work, not someone else's project photos.

When you've completed these steps, you'll know exactly whether that 8-1/4 inch upgrade makes sense for your specific workflow, or if you've been overlooking simple setup improvements that would transform your current 7-1/4 inch saw. Either way, you'll gain confidence through predictable results, not marketing promises.